Growth and Capabilities of a Modern shanghai pcb assembly factory

Understanding the Role of PCB Assembly in Today’s Electronics

The electronics industry depends heavily on advanced manufacturing facilities capable of producing precise and reliable circuit assemblies. A shanghai pcb assembly factory plays an important role in delivering high-quality electronics for global markets. With Shanghai recognized as a major technology hub, these factories operate with advanced automation, skilled engineering teams, and strict quality processes to meet a wide range of industry demands.

Why Shanghai Has Become a Leading Hub for Electronics Manufacturing

Shanghai has emerged as a key destination for electronics manufacturing because of its strong industrial foundation, access to global supply chains, and highly trained technical workforce. Companies around the world prefer working with factories in this region due to the combination of efficient production, cost effectiveness, and modern technological capabilities.

Strong industrial ecosystem

Shanghai maintains one of the most advanced electronics ecosystems, with suppliers, component distributors, testing labs, and logistics partners located close to one another. This reduces production delays and improves communication between all stages of manufacturing.

Skilled engineering talent

Factories in Shanghai benefit from a large pool of engineers who specialize in circuit design, quality control, automation, and manufacturing optimization. Their expertise helps improve the accuracy and reliability of every project.

Advanced manufacturing infrastructure

With cutting-edge machinery and well-developed facilities, factories in Shanghai are equipped to handle both low-volume prototypes and large-scale production runs.

Core Processes Inside a shanghai pcb assembly factory

A modern assembly facility follows a structured and organized production cycle to ensure consistent quality. Each stage of the process supports the next, and any errors must be eliminated early to prevent issues later on.

Preparation and data verification

Before production begins, the engineering team reviews assembly files, layout designs, and component lists. This step ensures that the production line receives correct and complete data. Early verification avoids misplacements, missing parts, and assembly errors.

Component sourcing and inspection

Reliable sourcing is one of the most important steps in the electronics supply chain. A shanghai pcb assembly factory typically partners with Shanghai PCB Assembly Factory certified suppliers to secure genuine and high-quality components. Upon arrival, components are inspected to confirm authenticity, specifications, and performance.

Solder paste printing

A stencil printer applies solder paste to designated areas on the PCB. This step requires accuracy because too much or too little paste can affect solder joints. Advanced printers check alignment and ensure a consistent layer across the board.

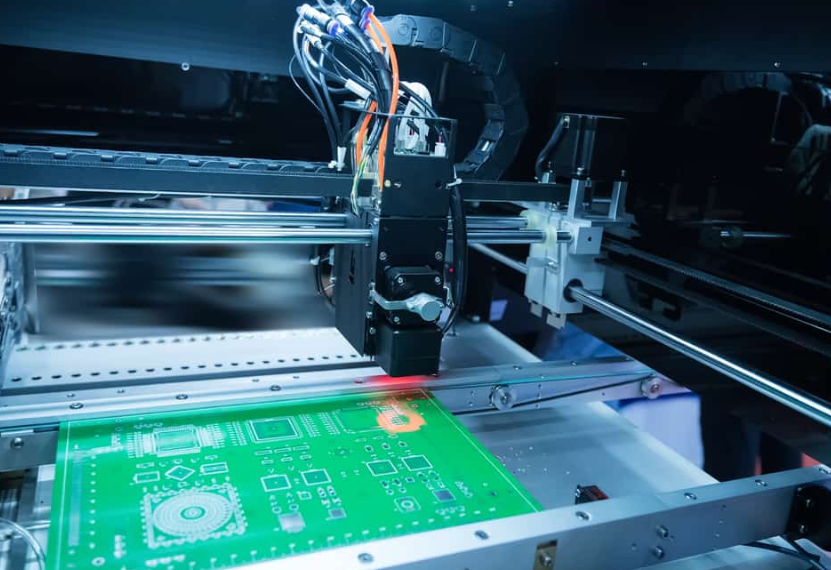

Automated SMT placement

Surface-mount components are placed using highly accurate pick-and-place machines. These machines operate at exceptional speed while maintaining precise alignment. The equipment can handle a wide variety of component sizes, from tiny resistors to large integrated circuits.

Reflow soldering

After placement, the board travels through a reflow oven where heat melts the solder paste. A carefully controlled temperature profile ensures proper melting and solidification, forming stable electrical connections between components and the board.

Through-hole processing

Some boards require both surface-mount and through-hole components. For these parts, automated selective soldering or wave soldering techniques are used depending on the design and batch size.

See also: Exploring the Latest in Gaming PC Australia: Trends and Tech

Quality Control Measures Used in Professional Assembly Lines

Factories in Shanghai maintain high standards of quality control throughout the production process. Since global markets expect consistency and reliability, each board undergoes multiple inspections.

Automated optical inspection

Cameras scan the entire board to detect misplaced components, solder bridges, missing pads, or other production errors. This automated inspection step improves accuracy and reduces human oversight.

X-ray inspection

For boards with hidden solder joints, such as those using BGA or QFN components, X-ray inspection is used to view internal connections. This helps identify issues like voids, insufficient solder, or misalignments.

Functional circuit testing

To ensure the board works under real conditions, electrical tests simulate actual operational requirements. If a board fails, technicians diagnose the cause and perform repairs before retesting.

Final review and packaging

Once all tests are complete, the board undergoes a final review where technicians check the overall quality, cleanliness, and compliance with customer requirements. The product is then packaged securely to prevent damage during shipping.

Industries That Depend on a shanghai pcb assembly factory

The versatility and precision offered by Shanghai-based assembly facilities attract clients from many different sectors. These industries rely on reliable and long-lasting electronic assemblies.

Automotive and electric vehicles

Modern vehicles require advanced electronics for navigation, sensors, engine control, battery management, and safety systems. Factories in Shanghai are equipped to meet the strict reliability and durability standards of the automotive sector.

Medical technology

Medical devices must meet strict regulatory guidelines for accuracy and safety. Factories in Shanghai use advanced testing techniques and high-quality components to support medical electronics manufacturing.

Industrial automation

Factories worldwide depend on control systems, industrial robots, and monitoring equipment. Shanghai’s assembly facilities deliver durable PCBs that perform well in harsh environments such as factories, warehouses, and outdoor applications.

Consumer electronics

Devices like televisions, audio systems, gaming equipment, smart home devices, and personal health gadgets rely on high-volume electronic assemblies. The scalability of Shanghai-based factories makes them ideal for mass production.

Challenges Faced by PCB Assembly Facilities in Shanghai

Despite technological advancements, factories in Shanghai face several industry-wide challenges that require innovation and constant improvement.

Component supply issues

Global shortages of microchips and semiconductors can affect production timelines. Factories must maintain strong supplier relationships and plan inventory carefully to avoid delays.

Tightening quality requirements

As products become more advanced, quality standards become stricter. Factories must continuously improve testing and inspection protocols to meet international expectations.

Growing complexity of product designs

New electronic devices often require miniature components, high-density layouts, and multilayer boards. This requires factories to invest in new equipment and advanced engineering strategies.

Rising demand for customization

Companies increasingly request customized electronics rather than standard designs. This requires flexible production lines and experienced engineering support.

Trends Shaping the Future of PCB Assembly in Shanghai

To stay competitive, factories in Shanghai are embracing new technologies, processes, and strategies.

Integration of smart manufacturing systems

Artificial intelligence, sensors, and real-time monitoring tools help improve accuracy and optimize production schedules. Smart factories can detect issues early and adjust operations automatically.

Use of environmentally friendly materials

Sustainability is becoming a major priority. Factories are adopting lead-free solder, energy-efficient production lines, and recyclable packaging materials.

Growth of flexible and wearable electronics

As demand for wearable health devices and flexible displays rises, assembly lines must adapt to new circuit materials and designs that differ from traditional rigid boards.

Greater focus on local production

Many global brands are shifting to closer-to-market manufacturing to reduce supply chain risks. Shanghai’s strong infrastructure positions it as a strategic location for regional production.

Conclusion

A shanghai pcb assembly factory represents the advanced capabilities and modern techniques that define today’s electronics industry. From detailed engineering to high-speed automation and strict testing processes, these factories ensure that every circuit board meets global standards for reliability and performance. With continued innovation, strong supply chain networks, and growing industry expertise, Shanghai will remain a key leader in the world of electronic manufacturing for years to come.