Why Remanufactured Diesel Parts Are a Cost-Effective and Eco-Friendly Alternative

Have you ever wondered what happens to diesel engine parts after they wear out or fail? Many people assume these components are discarded and replaced with new ones. In practice, many diesel parts can be restored and reused through remanufacturing, offering both financial and environmental advantages.

Remanufactured diesel parts have become a practical option for equipment owners, fleet managers, and mechanics who want dependable performance without the high cost of new components. These parts also reduce waste and support responsible use of materials.

In this article, we will explain what remanufactured diesel parts are, how they are rebuilt, and why they are widely viewed as a cost-effective and eco-friendly alternative.

What Are Remanufactured Diesel Parts

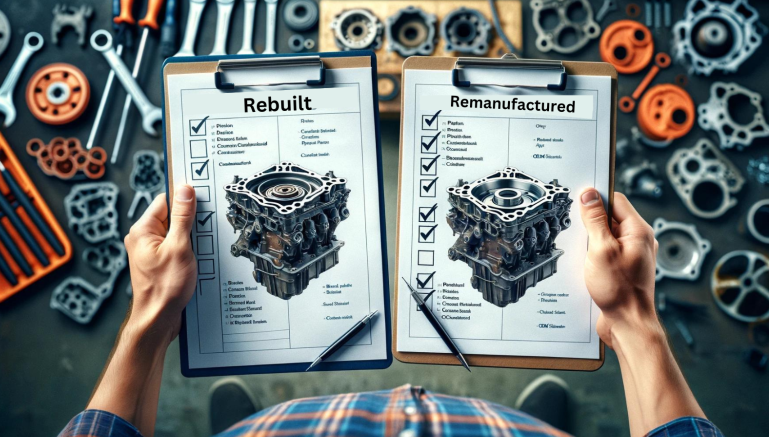

Remanufactured diesel parts are used components that have been restored to meet functional performance standards. Unlike basic repairs, remanufacturing follows a structured process designed to return parts to reliable working condition.

These parts are fully disassembled, inspected, cleaned, and rebuilt using a combination of reused and new components where required. The focus is on restoring functionality rather than simply extending short-term use.

How Remanufactured Parts Differ from Used Parts

Used diesel parts are typically removed from equipment and sold in their existing condition. They may function temporarily but often come with uncertainty regarding wear and remaining service life.

Remanufactured parts undergo inspection, rebuilding, and testing before reuse. This additional processing makes them more dependable than used parts and better suited for ongoing diesel applications.

The Remanufacturing Process Explained

Remanufacturing follows a structured process designed to restore diesel parts to reliable working condition. Each stage focuses on identifying wear, correcting issues, and confirming that the component can perform consistently once returned to service.

Inspection and Disassembly

The remanufacturing process begins with complete disassembly of the component. Each part is examined for wear, cracks, or damage that could affect performance. This step helps determine which elements can be reused and which require replacement.

Disassembly also allows technicians to evaluate internal areas that are not visible during normal operation. Identifying hidden issues early helps reduce the risk of failure once the part is back in service.

Cleaning and Surface Restoration

After inspection, all components are thoroughly cleaned to remove oil residue, carbon buildup, and contaminants. Specialized cleaning methods are used to restore surfaces without altering critical dimensions.

Surface restoration prepares components for accurate reassembly and proper fit. Clean parts also allow precise measurements, which helps confirm that tolerances fall within acceptable ranges.

Replacement of Worn Components

Components that experience regular wear, such as seals, bearings, and internal moving parts, are replaced during remanufacturing. These replacements help restore reliable operation and reduce the chance of future issues.

Using new components where necessary allows remanufactured parts to perform consistently under load. This step plays an important role in extending service life.

Testing and Quality Checks

Before approval, remanufactured parts are tested to confirm proper operation. Testing may include pressure checks, flow testing, or simulated operating conditions depending on the part type.

Quality checks help verify that the component functions within expected parameters. This final step supports consistent performance in diesel applications.

See also: How Digital Marketing Services for Small Business Can Boost Growth?

Cost Benefits of Remanufactured Diesel Parts

One of the main reasons remanufactured diesel parts are widely used is their financial advantage. By restoring existing components instead of producing new ones, these parts help reduce repair costs while still supporting dependable equipment operation.

Lower Purchase Cost

Remanufactured diesel parts generally cost less than new components because existing materials are reused. This lower upfront cost makes repairs more accessible, particularly for large or specialized equipment.

Lower part costs allow businesses to manage maintenance budgets more effectively while keeping equipment operational.

Reduced Downtime Costs

Affordable replacement parts can lead to faster repair decisions and shorter downtime. When repairs are completed quickly, equipment can return to service without extended interruptions.

Reducing downtime supports productivity and helps prevent delays that affect daily operations.

Budget-Friendly Maintenance

Using remanufactured parts supports more predictable maintenance planning. Manageable costs make it easier to schedule routine repairs rather than postponing service.

Over time, consistent maintenance helps reduce unexpected failures and larger repair expenses.

Environmental Advantages of Remanufactured Diesel Parts

Beyond cost savings, remanufactured diesel parts offer clear environmental benefits. By extending the life of existing components, remanufacturing helps reduce waste, conserve resources, and limit the energy required for part production.

Reduced Material Waste

Remanufacturing keeps large metal components in use instead of sending them to landfills. Many diesel parts remain structurally sound even after years of operation.

Reusing these components helps reduce industrial waste and supports responsible material use.

Conservation of Raw Materials

Producing new diesel parts requires raw materials such as steel and aluminum. Remanufacturing reduces demand for these materials by extending the life of existing components.

This approach helps limit resource extraction and processing, supporting more sustainable practices.

Lower Energy Consumption

Manufacturing new components requires significant energy. Remanufacturing typically uses less energy because it focuses on restoration rather than full production.

Lower energy use contributes to reduced environmental impact and more efficient resource management.

Performance and Reliability Considerations

A common question surrounding remanufactured diesel parts is whether they can match the performance of new components. Reliability depends largely on the remanufacturing process, including inspection standards, component replacement, and final testing, all of which play a critical role when selecting a fuel injector for sale.

When parts are rebuilt using proven methods and quality replacement components, they can perform consistently under normal operating conditions. Proper installation and routine maintenance also play an important role in supporting dependable long-term use.

A Practical Alternative for Modern Diesel Maintenance

Remanufactured diesel parts offer a practical option for maintaining equipment without unnecessary expense or waste. By restoring existing components, they support reliable operation while helping control repair costs and reduce environmental impact.

With careful part selection and correct installation, remanufactured components can support efficient diesel engine performance over time. This balanced approach makes remanufactured diesel parts a practical choice for maintaining performance while managing long-term costs and environmental impact.

Frequently Asked Questions

Are remanufactured diesel parts reliable?

Remanufactured parts can be reliable when rebuilt using proper inspection, testing, and quality components. Performance depends on correct installation and application.

How do remanufactured parts compare to new parts?

Remanufactured parts typically cost less and restore original functionality. New parts may include design updates, while remanufactured parts focus on performance restoration.

Are remanufactured diesel parts better for the environment?

Yes. Remanufacturing reduces waste, conserves raw materials, and uses less energy than producing new parts.