Advancements in Aluminum CNC Machining Parts for Precision Manufacturing

Introduction to Aluminum CNC Machining

In today’s industrial world, precision and efficiency are essential. Aluminum cnc machining parts have emerged as vital components across numerous industries. These parts combine the lightweight and corrosion-resistant properties of aluminum with the accuracy of CNC (Computer Numerical Control) technology. The result is a product that is highly durable, precise, and suitable for a variety of demanding applications.

CNC machining allows manufacturers to produce complex designs with consistent quality, making it indispensable for sectors like aerospace, automotive, medical devices, and electronics. Aluminum is particularly advantageous because it is easy to machine, lightweight, and capable of maintaining structural integrity under different conditions.

Key Benefits of Aluminum CNC Machining Parts

Lightweight and High Strength

Aluminum cnc machining parts are favored for their low weight and high strength. Reducing component weight is critical in applications like aviation and automotive engineering because it enhances performance and fuel efficiency. At the same time, aluminum maintains sufficient strength to handle mechanical stresses and ensure long-term reliability.

Exceptional Precision and Repeatability

CNC machining enables parts to be manufactured with precise dimensions and tight tolerances. This ensures that each aluminum cnc machining part meets the required specifications, minimizing errors during assembly. The repeatability of CNC processes allows for large-scale production while maintaining consistent quality across batches.

Corrosion Resistance and Longevity

Aluminum naturally resists corrosion, making these aluminum cnc machining parts suitable for harsh environments. Components exposed to moisture, chemicals, or fluctuating temperatures maintain their integrity and appearance over time, reducing maintenance needs and extending service life.

Thermal and Electrical Conductivity

Aluminum offers excellent thermal and electrical conductivity. CNC machining allows the creation of components such as electronic housings and heat sinks that require these properties. The combination of precision design and aluminum’s conductivity ensures optimal performance in electronics and energy applications.

See also: Exploring the Latest in Gaming PC Australia: Trends and Tech

Applications in Various Industries

Aerospace and Aviation

In aerospace, aluminum cnc machining parts are used for brackets, housings, structural elements, and engine components. Their lightweight nature reduces fuel consumption and enhances aircraft efficiency. CNC machining ensures that these components meet stringent aerospace standards, which require extreme precision and reliability.

Automotive Industry

Aluminum cnc machining parts play a critical role in modern vehicles. Engine components, transmission parts, and suspension elements benefit from aluminum’s lightweight and strength. CNC technology allows automotive manufacturers to produce highly accurate parts that fit perfectly and improve overall vehicle performance.

Medical Devices

Precision is critical in the medical field. Aluminum cnc machining parts are utilized in surgical instruments, diagnostic equipment, and housings for medical electronics. CNC machining ensures these parts meet strict tolerance requirements, providing safety and effectiveness for medical applications.

Electronics and Consumer Products

Aluminum’s conductivity and lightweight properties make it suitable for electronic housings, heat sinks, and structural components in consumer devices. CNC machining allows for the production of intricate designs that improve cooling, performance, and durability.

The Manufacturing Process

Selection of Aluminum Alloy

The choice of aluminum alloy is crucial in manufacturing aluminum cnc machining parts. Common alloys include 6061, 7075, and 2024. Each alloy offers unique characteristics such as tensile strength, corrosion resistance, and machinability. Selection depends on the intended application and required performance.

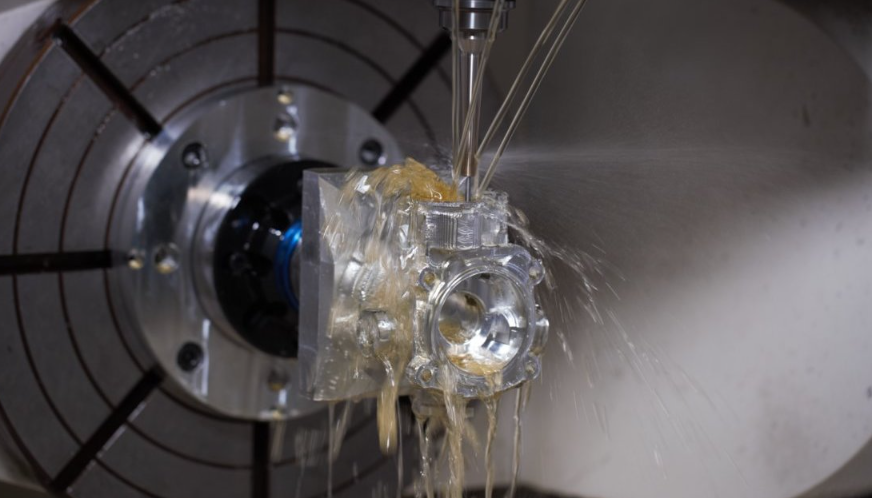

CNC Machining Techniques

Several techniques are used to manufacture aluminum components:

- Milling: Creates flat surfaces, slots, and complex geometries.

- Turning: Produces cylindrical shapes and symmetrical components.

- Drilling: Provides precise holes for assembly and installation.

- Finishing Processes: Grinding, polishing, and deburring refine surface quality and ensure dimensional accuracy.

Each step follows a computer-controlled program to achieve maximum precision and efficiency.

Quality Assurance

Quality control is critical in the production of aluminum cnc machining parts. Measurements using coordinate measuring machines (CMM), calipers, and micrometers verify tolerances and surface finishes. Rigorous inspection ensures components meet specifications before delivery.

Design Considerations

Wall Thickness and Durability

Optimizing wall thickness is important to maintain strength without increasing weight unnecessarily. Proper design prevents deformation during operation and ensures longevity.

Tolerances and Fit

Maintaining tight tolerances is essential for accurate assembly. CNC machining provides high precision, allowing components to fit together seamlessly and perform reliably.

Surface Finish

Surface finish affects both function and aesthetics. Smooth finishes can reduce friction in mechanical assemblies and improve the visual appeal of consumer products.

Complexity vs. Cost

While CNC machining allows for complex designs, overly intricate parts may increase production costs and time. Balancing complexity with manufacturability ensures cost-effective production without sacrificing quality.

Advantages Compared to Other Materials

Compared to steel and plastic, aluminum cnc machining parts provide a superior balance of lightweight, strength, and corrosion resistance. Steel is strong but heavier and harder to machine, while plastic is lightweight but lacks durability and thermal stability. Aluminum offers a versatile solution suitable for a wide range of applications.

Future Trends

Automation and Smart Manufacturing

Integration of automation, artificial intelligence, and IoT in CNC machining processes improves efficiency, reduces waste, and enhances precision. These technologies enable manufacturers to produce high-quality aluminum parts more efficiently.

Advanced Alloys

Research continues to produce new aluminum alloys with higher strength, better corrosion resistance, and improved thermal performance, expanding the range of potential applications.

Sustainable Manufacturing

Sustainable practices, including recycling aluminum and energy-efficient machining, are gaining importance. Aluminum cnc machining parts can be manufactured with minimal environmental impact while maintaining high quality.

Conclusion

Aluminum cnc machining parts are essential for modern manufacturing due to their precision, durability, and versatility. Industries such as aerospace, automotive, medical, and electronics benefit from the lightweight, strong, and corrosion-resistant properties of aluminum. With advances in CNC technology, material science, and sustainable manufacturing, aluminum cnc machining parts will continue to play a key role in producing high-performance, reliable components for a wide range of applications.