The Growing Demand for Aluminum Die Casting Services in Modern Industry

In today’s fast-paced manufacturing world, companies are constantly on the lookout for solutions that combine strength, precision, and efficiency. One of the most reliable and scalable methods in metal part production is aluminum die casting services. These services have become essential across industries such as automotive, electronics, aerospace, energy, and even consumer goods. Whether it’s engine housings, LED light fixtures, or handheld tools, aluminum die casting continues to redefine the boundaries of performance and design.

This article explores the scope, benefits, industries served, and future trends surrounding aluminum die casting services—and why businesses increasingly depend on them for reliable, large-scale component manufacturing.

What Are Aluminum Die Casting Services?

Aluminum die casting services refer to specialized manufacturing processes provided by companies equipped to produce high-volume, complex aluminum components through die casting. This technique involves injecting molten aluminum into precision-engineered steel molds (dies) under high pressure. Once the metal solidifies, it forms parts with tight tolerances, clean surfaces, and detailed geometries.

Professional aluminum die casting services include not only the casting process but also pre-production design consultation, die manufacturing, secondary machining, finishing, and even assembly.

See also: Inside the Tech: How Permanent HWID Spoofers Work to Keep You Unbanned

Why Aluminum? A Preferred Metal for Die Casting

Aluminum is prized for several unique characteristics:

- Lightweight but strong: Offers the best strength-to-weight ratio among commonly used casting metals.

- Corrosion-resistant: Ideal for harsh environments or outdoor applications.

- Good thermal and electrical conductivity: Perfect for heat sinks and housings.

- Recyclable: Environmentally sustainable, with minimal energy requirements during recycling.

- Non-toxic and safe: Useful for food-grade and medical components.

These properties make aluminum the ideal candidate for high-performance components across several verticals.

Features of Professional Aluminum Die Casting Services

1. Custom Mold Design

Top-tier die casting service providers use advanced CAD/CAM software to design custom molds that align perfectly with your part specifications, ensuring smooth injection and high repeatability.

2. Rapid Prototyping

With the use of simulation software and 3D printing, many companies offer fast prototyping to test the geometry, tolerances, and performance before full-scale production.

3. High-Pressure Casting

Most aluminum die casting services involve high-pressure casting, which enables faster cycle times and finer detail capture, especially in thin-walled parts.

4. Post-Processing Capabilities

Many providers offer value-added services such as CNC machining, surface finishing (like powder coating or anodizing), assembly, and quality testing to deliver ready-to-use parts.

5. Quality Assurance

Advanced inspection techniques, including X-ray testing, coordinate measuring machines (CMM), and tensile testing, ensure high-quality outputs from every production batch.

Benefits of Outsourcing Aluminum Die Casting Services

✔️ Cost Efficiency at Scale

Once the mold is created, each unit can be produced at a low cost per part—ideal for high-volume production.

✔️ Precision and Consistency

Die casting delivers parts with tight tolerances and repeatable quality, reducing the need for extensive post-processing.

✔️ Faster Turnaround Times

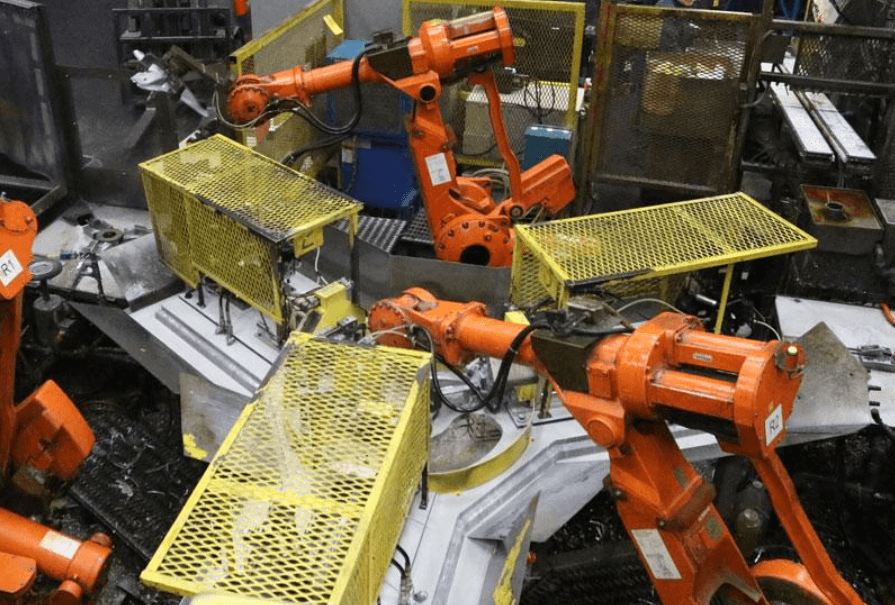

Modern die casting facilities operate with robotic automation and efficient cycle times, minimizing lead times.

✔️ Enhanced Design Flexibility

Complex geometries, undercuts, logos, and text can all be molded directly, eliminating additional fabrication steps.

✔️ Sustainability

Since aluminum is 100% recyclable, many companies now offer green casting solutions that reuse leftover metal from previous batches.

Major Industries Relying on Aluminum Die Casting Services

🚗 Automotive

Parts like gearboxes, clutch housings, engine brackets, and dashboard components are commonly die-cast. The industry’s shift toward electric vehicles has further increased the demand for lightweight, heat-conductive components.

✈️ Aerospace

Aircraft components need to be lightweight yet structurally sound. Die casting services provide cost-effective alternatives to machined or forged parts for non-critical components.

📱 Electronics

From LED lighting to mobile phone frames and battery enclosures, electronics manufacturers depend on aluminum die casting services to deliver compact and heat-efficient designs.

🏥 Medical Equipment

High-precision castings for surgical tools, imaging devices, and diagnostic equipment demand the quality and reliability offered by die casting.

🏠 Consumer Appliances

Air conditioners, blenders, fans, and other home appliances often incorporate aluminum components made using die casting.

Key Considerations When Choosing Aluminum Die Casting Services

If you’re looking to work with a service provider, these are some important factors to evaluate:

✅ Experience and Expertise

Look for companies with years of experience and a strong track record in your industry. Knowledge of regulatory standards (such as ISO, RoHS) is a plus.

✅ Material Selectiones

Tooling is the biggest upfront investment. Ask if the service provider offers in-house tool design and maintenance to minimize downtime.

✅ Scalability

Whether you need 1,000 or 100,000 parts, make sure the vendor can scale up without compromising quality.

✅ Quality Control

Inquire about their inspection protocols and certifications like ISO 9001 or IATF 16949 for automotive-grade production.

Technological Trends in Aluminum Die Casting Services

🔍 Simulation-Driven Die Design

Many manufacturers now use simulation tools to predict metal flow, temperature gradients, and potential defects, optimizing dies before the first cast is made.

🤖 Industry 4.0 Integration

With IoT sensors and real-time data analytics, die casting machines can now self-correct during production, ensuring consistent output and reducing material waste.

🌍 Eco-Friendly Casting

From using recycled aluminum ingots to low-VOC lubricants, the industry is moving toward greener processes. Some facilities even operate with closed-loop water cooling systems.

🧠 AI and Machine Learning

Advanced AI models are being used to analyze casting parameters and predict failures, increasing yield and reducing downtime.

Conclusion: The Strategic Edge of Aluminum Die Casting Services

In a highly competitive market, manufacturers cannot afford errors, delays, or inconsistent parts. This is where aluminum die casting services step in—offering not just a method of production but a strategic edge in terms of quality, speed, and cost-effectiveness.

From design to post-processing, today’s die casting providers act as manufacturing partners rather than just vendors. Their ability to turn raw aluminum into complex, precise, and reliable components is key to product success in nearly every major industry.

If you’re aiming for scalable manufacturing with long-term reliability and aesthetic finish, aluminum die casting services offer a solution that checks all the boxes. As the industry evolves with smarter technologies and sustainable practices, now is the best time to explore what these services can do for your production line.