Boosting Food & Beverage Processing Efficiency with Robotics in 2026

The food and beverage manufacturing landscape in 2026 is defined by a single, pressing reality: the margin for error has effectively vanished. With operational costs rising and consumer demand for transparency hitting new peaks, many processors are no longer looking at robotics as a futuristic luxury. Instead, automation is becoming the standard infrastructure required to keep lines running, costs down, and shelves stocked.

For facility managers and production leads, the conversation has shifted. In leading facilities, we are moving past the pilot programs of the early 2020s. The focus now is on practical, high-yield integration where machines don’t just move products but actively make decisions to optimize throughput.

The Evolution of “Smart” Processing

In previous years, automation was largely about mechanical repetition, moving a box from point A to point B. In 2026, the efficiency gains come from the cognitive layer added on top of these mechanical actions. Robotics are now deeply intertwined with artificial intelligence, allowing systems to adapt to variability in real-time without stopping the line.

Hyperspectral Imaging and Real-Time Sorting

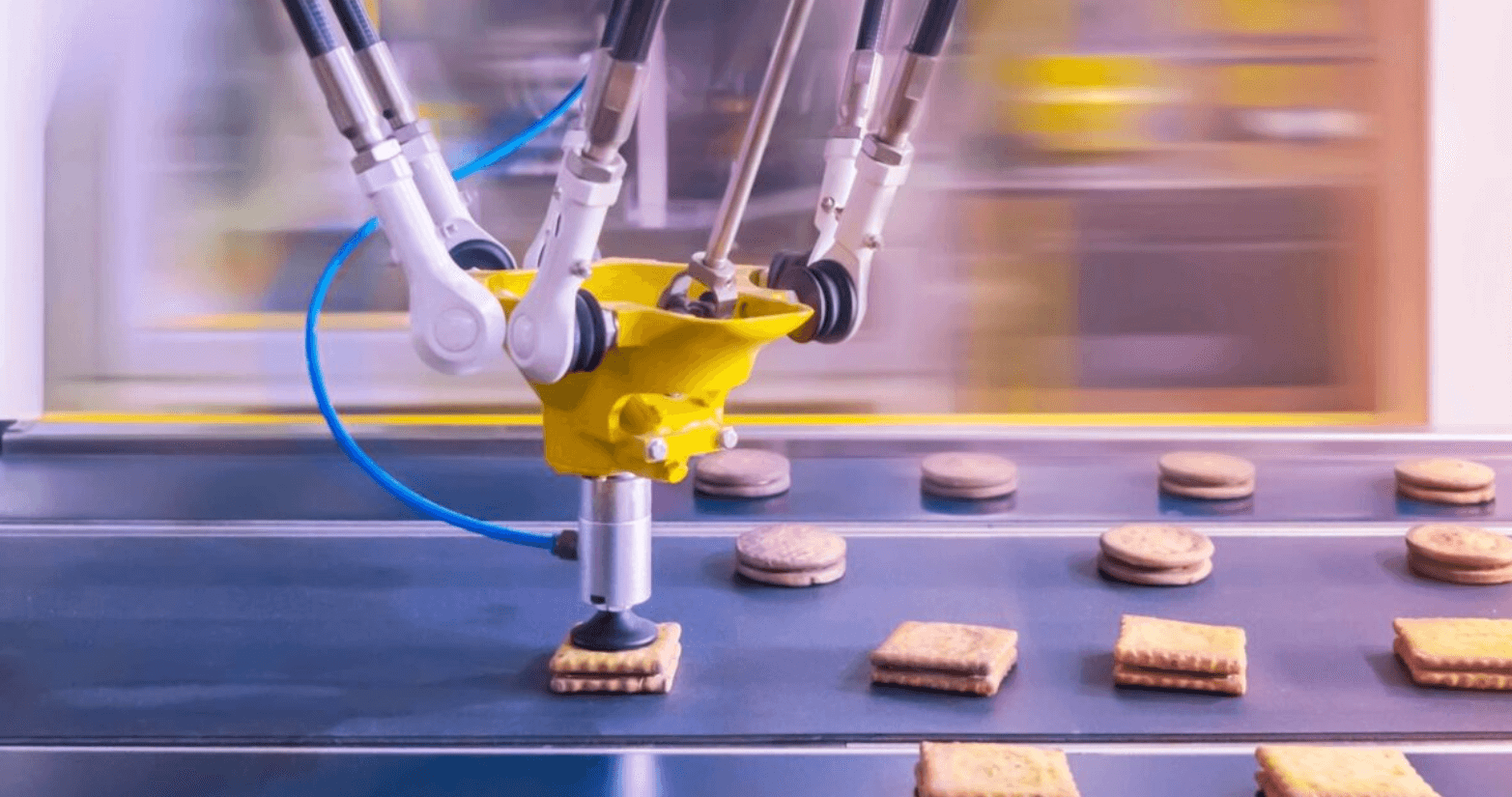

One of the most significant efficiency boosters this year is the widespread adoption of hyperspectral imaging coupled with robotic sorting. Traditional cameras could spot a bruised apple or a misshapen cookie, but they often missed internal defects or subtle chemical changes.

Newer robotic systems effectively “see” beneath the surface. For a beverage processor, this means a high-speed arm can identify and remove a bottle with a micro-leak or improper seal before it ever reaches the packaging crate. In produce processing, robots differentiate between a ripe avocado and one that is rotting from the inside, sorting them into different streams instantly.

While the initial integration of these advanced sensors requires significant capital and robust data infrastructure, the capability drastically reduces the volume of returns and protects brand reputation. Fewer recalls mean less wasted operational time, justifying the investment for high-volume lines.

Predictive Maintenance Loops

Unplanned downtime remains the biggest killer of efficiency (OEE). The difference in 2026 is that robots are now self-monitoring. We are seeing servo motors and robotic arms equipped with vibration sensors and thermal monitors that feed data back to a central system.

Instead of running a machine until a bearing seizes, the system alerts maintenance teams that a specific joint is showing signs of wear three weeks before a potential failure. This shifts maintenance from a panicked emergency repair at 2:00 AM to a scheduled, 20-minute swap during a shift change. The result is a production schedule that remains predictable and consistent.

Solving the Labor Continuity Problem with Cobots

The labor shortage in manufacturing wasn’t a temporary blip; it was a demographic shift. In response, the industry has heavily pivoted toward Collaborative Robots, or “cobots.” Unlike the massive, caged industrial arms of the past, cobots are designed to work safely alongside human staff, effectively plugging the gaps in the workforce.

High-Mix, Low-Volume Adaptability

A major hurdle for older automation was rigidity. If you wanted to switch from packing 12-ounce cans to 20-ounce bottles, retooling the robot could take a whole shift. Cobots in 2026 have solved this with “teach-by-demonstration” capabilities. A line operator can physically guide the robot arm through the new motion, and the system learns the path in minutes.

This flexibility is crucial for co-packers and facilities handling multiple SKUs. It allows a single production line to handle a breakfast cereal in the morning and a snack mix in the afternoon with minimal downtime. The efficiency here isn’t just speed; it is agility. The ability to say “yes” to smaller, more complex orders without tanking profitability is a massive competitive advantage.

Relieving Humans of the “Dull, Dirty, and Dangerous”

Efficiency drops when workers are fatigued or injured. Robotics are now taking over the most physically taxing roles in the plant. In meat processing, for example, automated butchery systems perform the heavy lifting and repetitive cutting tasks that famously cause repetitive strain injuries in human workers.

By shifting human talent to supervisory roles, managing the robots rather than acting as robots, facilities see lower turnover rates. Keeping a skilled operator on staff is far more efficient than constantly training new hires to replace those who burn out from the physical toll of the job.

Precision Control and Waste Reduction

Shrinkflation and rising raw material costs have made waste reduction a financial priority. Every gram of product that hits the floor or is overfilled into a package is lost revenue. Robotics in 2026 offers a level of precision that manual handling simply cannot match.

Automated Portioning and Filling

In the beverage sector, high-speed robotic fillers use flow meters and rapid-response valves to hit exact liquid levels within a fraction of a milliliter. Over the course of a million bottles, preventing even a 1% overfill translates to thousands of gallons of product saved.

Similarly, in solid food processing, robotic grippers with tactile feedback can pick up delicate items, like a frosted cake or a cluster of tomatoes, and place them into packaging without crushing them. Previous generations of hard grippers caused product damage that had to be discarded. The new wave of “soft robotics,” utilizing food-grade silicone fingers and air pressure, handles product as gently as a human hand but with the speed of a machine.

Upcycling Waste Streams

A newer trend driving efficiency is the automated recovery of byproducts. Advanced sorting robots can divert food waste that would normally go to a landfill into secondary processing streams. For instance, vegetable trimmings or fruit peels can be automatically separated and routed to a station for processing into animal feed or natural dyes.

This turns a disposal cost into a potential revenue stream, or at the very least, a neutral operational step. It maximizes the yield from every shipment of raw ingredients that enters the facility.

The Role of Data Integration

The hardware, the arms, grippers, and conveyors, is only half the equation. The other half is the data those machines generate. In 2026, successful processors are those who treat their robotics as data collection points.

Every time a robot picks an item, it records weight, size, and speed. This data creates a granular view of production health. If a robot on the packaging line starts slowing down to correct for misaligned boxes, the system flags the issue upstream at the carton erector. This holistic view allows managers to fine-tune the entire line, identifying bottlenecks that are invisible to the naked eye.

This connectivity extends to supply chain management. If the robotic palletizer knows exactly how many cases have been stacked, it can trigger an automatic signal to the warehouse management system to schedule a truck. This seamless flow from processing to logistics removes the administrative friction that often slows down shipping.

Read also: The Most High-Tech Hotels in the World Accepting Cryptocurrency Payments

Looking Forward: The Autonomous Facility

As we move through 2026, the trend line points toward greater autonomy. We are seeing the early stages of “lights-out” shifts in cold storage and freezing applications, where robots work in temperatures that are inhospitable to humans. These systems can run 24/7 without breaks, maximizing the utilization of expensive real estate and energy.

However, the goal is not entirely owner-operator independence. The human element remains critical for strategy, recipe development, and quality oversight. The robots are the tools that execute that strategy with unflagging consistency.

Summary of Operational Gains

The advanced robotics integration in food and beverage processing is delivering measurable results across the board. By 2026, the technology has matured from experimental novelty to reliable infrastructure for forward-thinking companies. Yield improvement is now driven by precision cutting and filling that minimizes product loss, while predictive maintenance keeps lines running during critical shifts. Simultaneously, workforce stability improves as cobots handle physical strain, retaining human talent for higher-level tasks, and quick changeovers allow facilities to adapt to changing consumer tastes instantly.

The processors winning in this market are those who view robotics not just as machinery, but as a strategy for resilience. By automating the variable and difficult parts of the process, they create a production environment that is stable, predictable, and ready for whatever market shifts come next.