CNC Milling: The Backbone of Precision Engineering and Modern Manufacturing

In the rapidly evolving world of manufacturing, precision, efficiency, and adaptability have become the driving forces behind innovation. As industries strive for tighter tolerances, complex geometries, and faster production CNC milling service has emerged as one of the most valuable technologies at the forefront of industrial development. From prototyping to full-scale production, CNC milling has transformed how manufacturers approach machining operations.

This article delves into the fundamentals, benefits, materials, and applications of CNC milling, and why it continues to be the cornerstone of modern-day manufacturing.

What is CNC Milling?

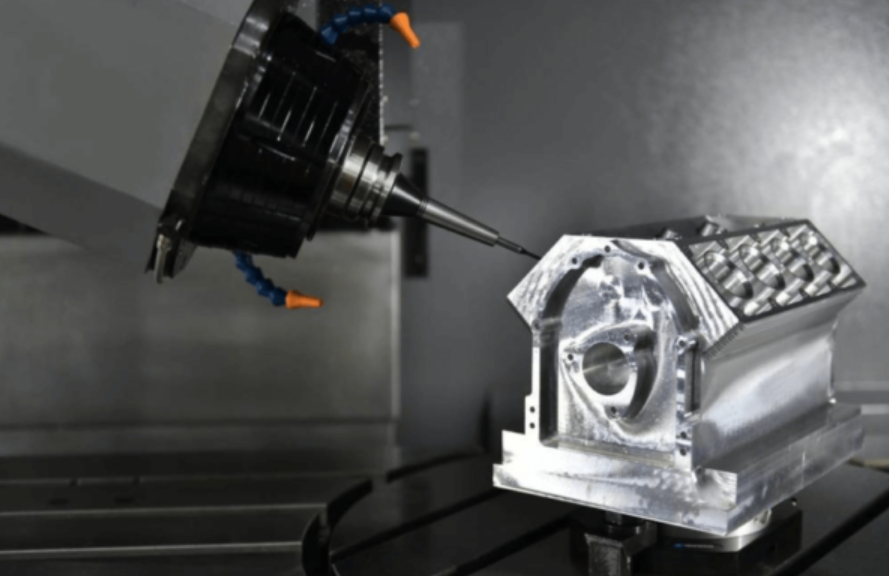

CNC milling—short for Computer Numerical Control milling—is a manufacturing process that uses rotary cutting tools to remove material from a solid workpiece. Unlike manual milling machines, CNC mills are guided by pre-programmed software (commonly created in CAD and CAM systems) that automates the movement of tools across multiple axes (X, Y, and Z).

By following precise digital instructions, CNC mills can execute complex tasks with repeatable accuracy and consistency. This makes them indispensable in industries where part integrity and dimensional precision are critical.

See also: AI Face Swap Technology in Live Performance Augmentation

The Key Components of CNC Milling Machines

To understand why CNC milling is so effective, it’s helpful to familiarize yourself with the core components of the system:

- Spindle: Holds and rotates the cutting tool.

- Worktable: Secures the workpiece using clamps or vises.

- Tool Changer: Automatically switches between tools for different operations.

- Control Panel: Interface used to input data and monitor machine functions.

- Drive Motors and Axes: Responsible for moving the tool and table in three (or more) directions.

Advanced CNC mills include 4-axis or 5-axis configurations, allowing for the creation of highly intricate parts in fewer setups.

Why CNC Milling is a Game Changer

The adoption of CNC milling across industries is no coincidence. Its advantages far surpass those of traditional manufacturing methods:

1. Precision and Accuracy

CNC milling delivers extraordinary precision, often achieving tolerances of ±0.001 inches or better. This level of detail is essential for aerospace, medical, and optical components.

2. High Repeatability

Once a program is verified, thousands of parts can be produced with consistent dimensions, eliminating human error from manual operations.

3. Complex Geometry Handling

CNC machines can mill intricate 3D shapes, undercuts, slots, threads, and contoured surfaces—designs that would be impractical or impossible with manual tools.

4. Efficiency in Production

With rapid tool movements and automated operations, CNC milling significantly reduces production time and boosts throughput, especially in large-scale manufacturing.

5. Less Waste, More Sustainability

By optimizing tool paths and material usage, CNC milling reduces waste, minimizes raw material costs, and supports environmentally conscious manufacturing.

Types of CNC Milling Machines

Depending on production needs and part complexity, different types of CNC milling machines are employed:

- Vertical Milling Machines (VMC): The spindle is vertically oriented; ideal for flat-surfaced and slot-based work.

- Horizontal Milling Machines (HMC): Spindle runs horizontally, enabling deeper cuts and higher material removal rates.

- Gantry Mills: Used for large, heavy parts such as engine blocks and molds.

- 5-Axis Milling Machines: Capable of moving the workpiece or cutting tool on five axes simultaneously—ideal for aerospace and medical-grade parts.

Common Materials Used in CNC Milling

CNC milling is highly adaptable to a wide range of materials, making it suitable for diverse applications:

- Metals: Aluminum, stainless steel, brass, copper, titanium, Inconel, tool steel.

- Plastics: Nylon, POM (Delrin), polycarbonate, PTFE, ABS, PEEK.

- Composites: Carbon fiber, fiberglass-based laminates for high-performance applications.

Each material may require customized tooling, spindle speeds, and feeds to ensure quality and avoid tool wear or overheating.

Industries Benefiting from CNC Milling

The sheer flexibility and precision of CNC milling make it applicable to nearly every major manufacturing sector:

Aerospace

Jet engine components, brackets, housings, and control surfaces require extremely tight tolerances. CNC milling provides the accuracy necessary for flight-critical parts.

Automotive

From engine blocks to gear housings, CNC milling creates parts that improve vehicle performance, reduce weight, and enhance durability.

Medical and Dental

Surgical tools, orthopedic implants, and custom dental prosthetics are manufactured using CNC mills due to their precision and sterility requirements.

Electronics

Printed circuit board housings, heat sinks, and connector bodies demand compact, intricate geometries—perfectly suited to CNC milling.

Industrial Equipment

Machine tool parts, pump casings, and motor mounts rely on robust and durable components made via milling processes.

The CNC Milling Process Step by Step

Understanding the CNC milling workflow gives insight into the speed and accuracy of the process:

- Design: Engineers create 3D CAD models of the part.

- CAM Programming: Tool paths and cutting strategies are generated.

- Machine Setup: Material is clamped onto the worktable and the program is uploaded.

- Machining: The tool executes programmed operations—milling, drilling, facing, contouring.

- Inspection: Finished parts undergo dimensional and surface checks to ensure accuracy.

Some services also include post-processing such as deburring, polishing, or anodizing.

Cost Considerations in CNC Milling

The cost of CNC milling services depends on several variables:

- Material type: Titanium and specialty alloys cost more to machine than aluminum or plastic.

- Part complexity: Multi-axis machining, tight tolerances, and detailed geometry increase setup and runtime costs.

- Batch size: Setup costs are distributed over larger volumes, lowering per-unit cost in mass production.

- Lead time: Rush jobs often carry a premium price.

Getting a clear quote from your CNC service provider with a breakdown of these factors is essential for budget planning.

Tips for Designing CNC-Milled Parts

To get the most out of a CNC milling service, designers should follow these best practices:

- Avoid extremely thin walls that may vibrate or break during cutting.

- Maintain uniform wall thickness to reduce thermal distortion.

- Use standard hole sizes that match tool availability.

- Include fillets in corners for better tool access and longer cutter life.

Many providers also offer Design for Manufacturability (DFM) consultations to optimize your design before production.

Conclusion: CNC Milling as a Pillar of Modern Manufacturing

In the landscape of precision manufacturing, CNC milling remains one of the most reliable, flexible, and accurate machining solutions. It bridges the gap between digital design and physical production, enabling innovation across nearly every industrial sector.

From simple aluminum brackets to complex aerospace components, CNC milling is not just a manufacturing method—it is a critical enabler of modern engineering excellence. As new technologies such as AI-assisted design, smart tooling, and additive-subtractive hybrids emerge, the role of CNC milling will only grow in prominence.