How Composite Ceramics Improve Toughness and Damage Resistance

Ceramics are known for their hardness, heat resistance, and chemical stability, yet they also have a reputation for brittleness. Traditional ceramic materials can crack suddenly when exposed to impact or high stress, limiting their use in demanding environments. To overcome this limitation, engineers and material scientists developed Composite Ceramics, a class of advanced materials designed to improve toughness and resistance to damage without sacrificing the strengths that make ceramics valuable.

Composite ceramics combine two or more different material phases into a single structure. This approach allows the material to absorb energy, resist crack growth, and survive harsh conditions that would cause conventional ceramics to fail. Today, composite ceramics are used in industries where reliability, safety, and long service life are essential. This article explores how composite ceramics improve toughness and damage resistance, explaining the mechanisms behind their performance in clear and simple terms.

Why Traditional Ceramics Struggle With Toughness

Traditional ceramics are strong and rigid, but they lack flexibility. When stress is applied, they do not deform gradually like metals. Instead, they store energy until a crack forms, then fail suddenly. This behavior is known as brittle fracture.

Brittleness limits the ability of conventional ceramics to handle impact, vibration, or uneven loading. Even small defects or surface flaws can become starting points for cracks. Once a crack begins to grow, there is little to stop it.

This challenge led to the development of composite ceramics. By combining different materials within a ceramic matrix, engineers found ways to control crack growth and improve overall durability.

What Are Composite Ceramics

Composite ceramics are materials made by combining a ceramic matrix with reinforcing components such as fibers, particles, or secondary ceramic phases. Each component plays a specific role in improving performance.

The ceramic matrix provides hardness, heat resistance, and chemical stability. The reinforcing phase adds toughness by interacting with cracks and stress in controlled ways. Together, they create a material that behaves differently from traditional ceramics.

The goal of composite ceramics is not to eliminate cracks entirely, but to slow them down, redirect them, or absorb energy before catastrophic failure occurs.

Understanding Toughness and Damage Resistance

Toughness refers to a material’s ability to absorb energy before fracturing. Damage resistance describes how well a material resists crack initiation and growth when exposed to stress or impact.

In traditional ceramics, toughness is low because cracks propagate easily. In composite ceramics, the internal structure interferes with crack movement. This improves both toughness and damage resistance.

These properties are especially important in applications where materials face repeated stress, sudden impact, or harsh operating conditions.

Crack Deflection as a Key Toughening Mechanism

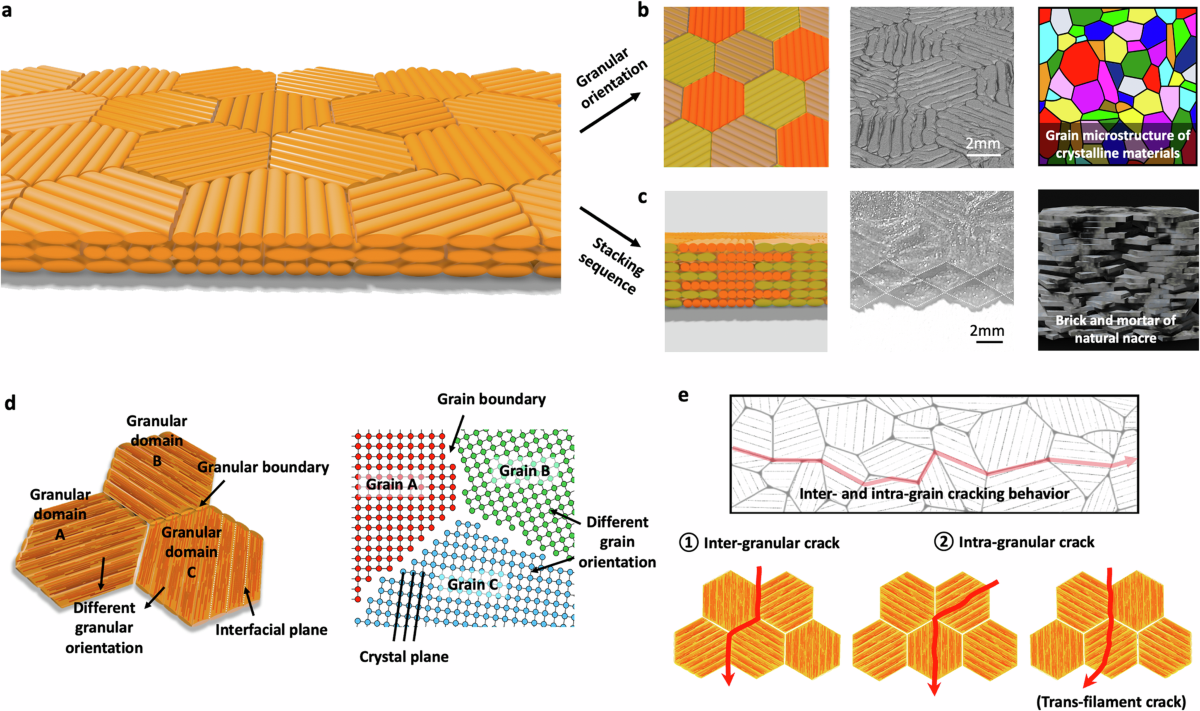

One of the most important ways composite ceramics improve toughness is through crack deflection. When a crack encounters a reinforcing phase inside the material, it is forced to change direction.

Changing direction requires energy. Each time a crack bends or twists, it loses momentum. This slows crack growth and reduces the chance of sudden failure.

Crack deflection also increases the length of the crack path. A longer path means more energy is needed for the crack to continue, further improving damage resistance.

Crack Bridging and Energy Absorption

Crack bridging occurs when reinforcing fibers or particles span across a growing crack. These reinforcements hold the crack faces together and resist further opening.

As stress increases, the bridging components absorb energy by stretching or pulling out from the matrix. This process dissipates energy that would otherwise drive crack growth.

Crack bridging is especially effective in fiber-reinforced composite ceramics, where long fibers provide continuous resistance to crack opening.

Load Transfer and Stress Redistribution

Composite ceramics improve damage resistance by redistributing stress away from critical areas. When a load is applied, stress is shared between the matrix and the reinforcing phase.

This load transfer reduces stress concentration at crack tips. Lower stress at these points slows crack initiation and growth.

By spreading stress more evenly, composite ceramics can handle higher loads without failure compared to traditional ceramics.

Microstructural Design and Its Impact on Toughness

The internal structure of composite ceramics plays a major role in their performance. Factors such as particle size, fiber orientation, and phase distribution influence toughness.

A well-designed microstructure ensures that cracks encounter reinforcing phases frequently. This increases the effectiveness of toughening mechanisms.

Manufacturing processes are carefully controlled to achieve the desired microstructure. Even small changes can significantly affect damage resistance.

Thermal Stability and Toughness at High Temperatures

Many applications expose materials to both mechanical stress and high temperatures. Composite ceramics maintain their toughening mechanisms under heat better than many other materials.

The reinforcing phases in composite ceramics remain stable at elevated temperatures. This allows crack deflection and bridging to continue even in extreme environments.

This combination of thermal stability and toughness makes composite ceramics suitable for aerospace, energy, and industrial applications.

Resistance to Wear and Repeated Damage

Damage resistance is not only about surviving a single impact. In many environments, materials face repeated stress and wear over time.

Composite ceramics resist surface wear because of their hardness, while their toughened structure prevents small cracks from growing into major failures.

This resistance to repeated damage extends service life and reduces maintenance needs in demanding applications.

Applications That Benefit From Tough Composite Ceramics

Industries that require reliable performance under stress benefit greatly from composite ceramics. Aerospace components face vibration, impact, and temperature extremes. Composite ceramics provide durability without excessive weight.

In energy systems, composite ceramics withstand heat and mechanical loads over long periods. Industrial tools and protective components benefit from their wear resistance and damage tolerance.

Medical and defense applications also rely on composite ceramics where strength, toughness, and reliability are critical.

Design Advantages Over Traditional Ceramics

Compared to traditional ceramics, composite ceramics offer greater design flexibility. Engineers can tailor properties by adjusting the type and amount of reinforcement.

This customization allows materials to be optimized for specific applications. Instead of choosing between strength and toughness, designers can achieve a balanced combination of both.

This adaptability is one of the reasons composite ceramics continue to gain importance across industries.

Read Also: How Smart Technology Is Transforming Luxury Homes for Sale

Manufacturing Challenges and Quality Control

Producing composite ceramics requires precise control over materials and processing conditions. Poor bonding between phases can reduce toughness instead of improving it.

Quality control ensures consistent microstructure and performance. Advanced processing techniques help maintain uniformity and reliability.

Despite these challenges, ongoing advancements continue to improve manufacturing efficiency and material quality.

Future Developments in Composite Ceramic Toughness

Research into composite ceramics continues to focus on improving toughness and damage resistance. New reinforcement materials and processing methods are being explored.

Innovations aim to further reduce brittleness while maintaining thermal and chemical stability. As technology advances, composite ceramics are expected to play an even larger role in high-performance applications.

These developments promise materials that are stronger, tougher, and more reliable than ever before.

FAQs About Composite Ceramics

Why are composite ceramics tougher than traditional ceramics?

Composite ceramics include reinforcing phases that interact with cracks, slowing or stopping their growth and allowing the material to absorb more energy before failure.

Do composite ceramics completely eliminate cracking?

No material is completely crack-proof. Composite ceramics control and slow crack growth, reducing the risk of sudden failure.

Are composite ceramics suitable for high-temperature environments?

Yes. Composite ceramics maintain toughness and structural stability at high temperatures, making them suitable for extreme conditions.

How do fibers improve damage resistance in composite ceramics?

Fibers bridge cracks and absorb energy as they stretch or pull out, preventing cracks from opening rapidly.

Are composite ceramics more expensive than traditional ceramics?

They can be more complex to manufacture, but their longer service life and improved performance often justify the cost.

Conclusion

Composite ceramics represent a major advancement in ceramic material technology. By combining multiple phases into a single structure, they overcome the brittleness that limits traditional ceramics. Through mechanisms such as crack deflection, crack bridging, and stress redistribution, composite ceramics significantly improve toughness and damage resistance.

These improvements allow composite ceramics to perform reliably in demanding environments where strength alone is not enough. As industries continue to seek materials that offer durability, stability, and safety, composite ceramics stand out as a solution that balances performance with resilience. Their continued development promises even greater capabilities in the future, reinforcing their role as a cornerstone of advanced engineering materials.